This guide will explain how to repair a failed or loose DC power jack on a laptop computer yourself.

Disclaimer: I’ve made these instructions only for people experienced with soldering and repairing computers. If you don’t feel comfortable doing this job, please do not open the laptop or you can permanently damage your computer. Take your laptop to a professional repair shop instead.

Use this repair guide at your own risk. 🙂

For this repair you’ll need the following tools.

1. Soldering iron or soldering station. I use Weller WES51 soldering station and for this job I set temperature to about 800-850°F.

2. I use high-tech rosin core silver-bearing solder from Radioshack with diameter 0.022″ ( Catalog #: 64-013 ). I think standard rosin core solder will work just fine.

3. Desoldering pump for removing solder around component leads. I use Edsyn Soldapullt pump, model DS 017.

4. 99% isopropyl alcohol and tooth brush for cleaning the motherboard from flux.

5. A new DC power jack.

Laptop DC power jack repair guide.

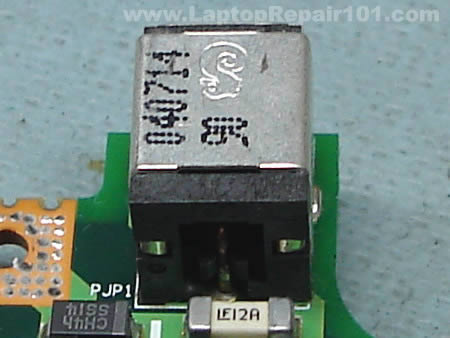

As you see on the following picture, the solder drop on the positive terminal looks different than on other three contacts. That’s where the problem is. The positive pin is not making a good contact with the motherboard and because of that power to the laptop cuts off when I move the power plug inside the power jack.

I’m going to desolder the power jack from the motherboard, clean contacts on both power jack and motherboard and then solder it back in place – this is the proper way fixing the power problem.

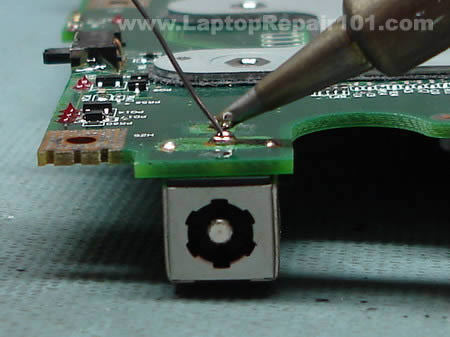

Start desoldering process with adding some new fresh solder to all three contacts. This will make old solder more flowable, easier to remove.

While heating one of the contacts, remove the solder from this contact using the desoldering pump. Repeat the same steps with all power jack contacts until you remove as much solder as possible.

Grab the power jack and carefully try removing it from the motherboard. Most likely you will not be able to remove the power jack the first time because there will be some solder bridges left between the contacts and traces on the motherboard. Carefully wiggle the power jack without applying any significant force and at the same time heat up all contacts one by one. This will help you to remove the power jack.

The DC power jack is almost removed from the motherboard.

Be careful. Inside the positive hole there is a copper sleeve which connects the terminal on one side of the motherboard with the traces on the other side. If you are removing the power jack with force, you can pull the sleeve from the hole. You don’t want to do that.

UPDATE: If you accidentally removed the internal sleeve, check out this post: How to fortify damaged power jack connection.

So, do not apply any force and make sure the solder is melted when you are removing the power jack. I hope you understand what I’m talking about.

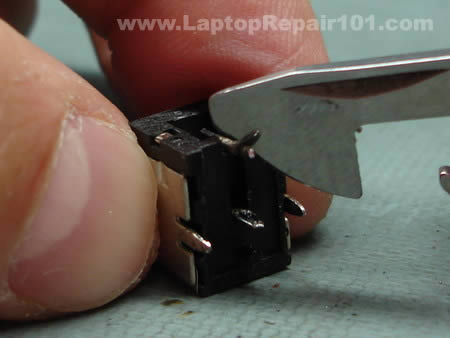

After the power jack is removed, clean all oxidized contacts with a knife.

Apply a fresh coat of solder to all contacts on the power jack.

The power jack terminals will look dirty because of melted flux.

You can remove the flux using the tooth brush and alcohol. It’s not necessary but it will make your job looking clean.

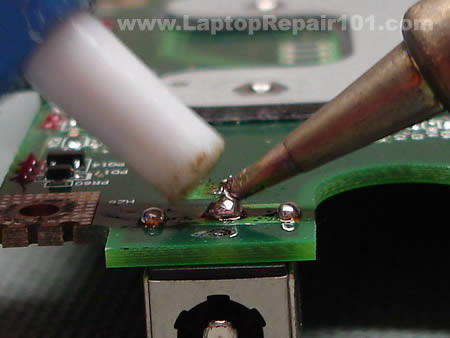

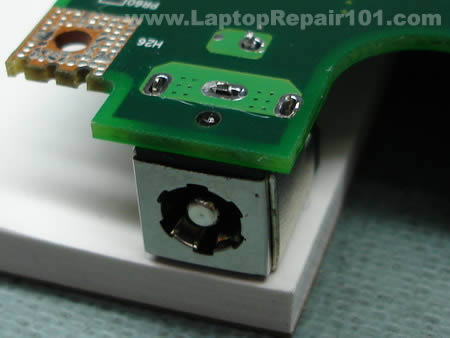

Apply a fresh coat of solder to all power jack terminals on both sides of the motherboard.

This side has been coated.

And this side has been coated too.

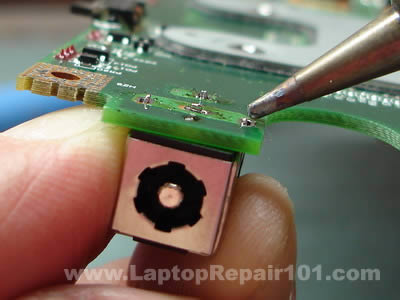

Now you can install the power jack back on the motherboard. Put something under power jack so there is no gap between the jack and the motherboard. Now you are ready to solder the jack back in place.

Solder all power jack pins.

The job is done and the laptop DC power jack is fixed. B-E-A-utiful!

Now just install the motherboard back into the laptop and you are done.

530 Responses

jbmurray

The dc jack area has broken 3 times (compac presario 2500). It is a fragile corner. Is there any ‘external physical support’ apparatus, that could suppot the area on the outside of the laptop, so that the area does not get so much pull/pressure on it?

David Chenault

Thank you for putting this on the internet in such a well organized easy to follow format. You are the Greatest man alive.

William Milkie

What an incredible site!

My son’s laptop has not worked for about a year.

While looking at it, and wiggling the power connector, I noticed the front lights flickering. Bad solder joint on the motherboard.

Using your directions, Toshiba A75-s226: I was able to take it apart, reflow the solder: made it slightly beefier, and repair it!

Good as new,

Thanks very much.

William Milkie

Jeff Finnan

I replaced the jack on a Dell Inspiron 1150. The battery is not charging. If I start up the 1150 with the AC adapter plugged in, I get a message that the AC power adapter cannot be determined and gives me some setup options. If the adapter is not plugged in, the 1150 starts up okay. However, my battery is just about dead.

Any suggestions?

Thanks,

Jeff

cj2600

Jeff Finnan,

Did you check the AC adapter? Maybe the adapter is dead?

Jeff Finnan

The charger is relatively new; however, there were some problems with the cord for it. I have ordered a new cord for it and will wait until it arrives.

I will report back.

Thanks,

Jeff

BlackTea

You are exactly right-on. My old laptop has exactly this loose power connection problem. You’re da Man!

Jeff Finnan

I discovered that I had an extra tip for the adapter, IGO 130. When I connected the one I had on the adapter, it would shut off. With the new tip, the battery started charging. Something must have happened to the tip, with the jack started loosening. It is my daughter’s laptop, she was pushing the tip around to get some intermittent charging until it would go no more. Now with new jack and tip, all appears well.

Thanks,

Jeff

Rob Nemlander

I have this power problem with my Toshiba Satellite P20 & will try to permanently repair my problem. My short term fix was to heat the power pin from the jack to the motherboard to repair the solder connection.

Now that I know how to take the laptop apart, I am going to attempt to replace the power pin with a piece of flexible wire so that the problem does not happen again.

I think the original cause was the flexing of the power pin & breaking away from the mother board when the power cord is flexing during usage.

Terry

Will any alcohol work or do I need 99% isopropyl alcohol?

Rob Miles

to Jeff Finnan about the Dell:

Some of Dell’s laptops look for a proprietary signal from the power supply sent through a 3rd pin. If they don’t see this signal, they will refuse to operate from AC power. This is to prevent you from using a 3rd party power supply, or one that isn’t matched to the current demands of that model notebook.

This 3rd wire is fragile and gets broken in the cable. This is most likely.

You could also have a problem at the jack which would be fixed by this guide. A 3rd possibility is that the PSU isn’t sending this signal anymore due to some internal failure – mine wouldn’t send when it was running off a battery back-up unit, for example, because it didn’t like the ‘dirty’ power input.

Contact Dell for a PSU swap.

Thomas

I had problems with my toshiba a75 s231. The battery would not charge and the power could not get to turn on my computer. Took it to a repair shop some 100 miles from my home and they told me that I would have to get a new mother board and other thing plus labor cost it would run around $650.00 to repair my computer. Then they told me that it would be better to just get a new computer instead of fixing it. I went back home thinking about buying a new one then I used my other computer to see if I could get help on the internet to fix it. After finding this sight I went to the store to buy me a soldering iron and took apart my computer for the first time. It wasn’t to hard and I got it fixed by my own hands and just paid $15.00 for the solder iron. Thanks for the step by step instructions I got my computer going and it feels realy good to know that their are people out there that can hep out and make a difference and save some major dollars. Mahalo nui loa, Thomas in Kona Hawaii

Donny

I ws wounder if you new y after i fix the dc jack the lights come on but thay go right off and the computer dose not come on

interphan

This is the most philanthropic site on the internet! I have been Googling for a site like this for hours for instructions to do it on my own and here it is! Thank you for your contributions to humanity and by undermining those swindlers who charge $280+ for this service. I am about to hit up Radio Shack to buy the supplies and do it on my own. I will update you on how it went! But one question that had been addressed before: is there an external physical apparatus that I can attach to the motherboard or jack that can provide extra support (i.e., to prevent this problem for ever occurring again?)

Thank you!

Wilson

Well I took apart my laptop and I need help with removing the power jack. I tried to desolder it using the iron and a desoldering band. The thing just won’t come out and the solder barely melts only at the exact point of contact. I’m using the generic $8 Radio Shack 15watt pencil solder. Any help is much appreciated.

Harlan

“Be careful. Inside the positive hole there is a sleeve witch connects the terminal on one side of the motherboard with the traces on the other side. If you are removing the power jack with force, you can pull the sleeve from the hole”

Is there a fix if you remove the sleve also?

cj2600

interhan,

I’m not sure if you can provide any extra support for the power jack soldered on the motherboard beside gluing it to the motherboard with epoxy, but it’s possible to relocate the power jack outside the laptop case. It doesn’t look sexy but it works. 🙂

Harlan

cj2600,

Thanks for the help and the link

manojtk

Great tutorial. I have had this problem on my toshiba m35x with battery not charging/DC jack loose contact for a long time and couple of days back it stopped charging completely, leading me to this site. I am a complete newbie wrt soldering and stuff, but I went ahead and bought all the equpiments suggested here for under 20 pounds, and it took me about six hours to dissemble the laptop again following the tutorial here, fix the soldering and put it back together. Needless to say it worked!!! Btw few variations between the instructions here and what I did

1. Didnt remove the modem card

2. Didnt remove the CPU

3. Didnt the remove the JACK completely – actually I tried but it was kind of stuck. So I just applied fresh solder on top of it.

Thanks again for putting together this tutorial. Great work!

wtf

im trying to do this and it is going well so far, but two screws on the base will NOT come out. my hands are bruised from applying so much vertical pressure to my screwdrivers. the screwdrivers are now all stripped. how the hell can i get these two things out?

John French

I’m about to start my third “repair effort” on my Toshiba. Couldn’t remove an F8 screw last time – had to drill into it with a small bit about the diameter of the screw threads – the screw head popped off and ran up the bit – later I was able to back the rest of the screw out of the base with needlenose pliers – I’ll replace the screw if I can get the Toshiba working. Other wise I’ll sell the whole mess cheap!

Brad

I have removed the power jack from the mother board successfully. I have a huge problem now……..The three holes are now filled with solder and I am having a hard time clearing them. I have tried using “wick” and I have also tried a solder pump, neither have been successful.

Does anyone have an idea as to how I can clear those holes so that I can reinsert a power jack? PLEASE help…….this site has been a life saver. Couln’t have gotten this far without it!!

cj2600

Brad,

Add some fresh solder into all three holes. Do not try installing the power jack at this time, just add some solder so the hole is filled up with the solder. Now melt the solder with the soldering gun and remove it with the pump.

Repeat the same process again: add solder – melt it – remove with the pump. Do it until the hole is clean. You have to repeat the same process a few times in a row for each hole. It’s very hard to clean the hole on the first try.

Usually I add/remove solder about 5-8 times until the hole gets clean.

Brad

cj2600,

Thanks for the quick reply! Can you please explain how adding more will clear out the holes? It seems as though each time I add, I am only picking up what I have added each time.

Do you think getting a smaller tip for my solder will hel with getting the excess that has filled the holes? Thanks……..looking forward to your help again.

MrBJ

I have the same problem. My holes are all blocked with Solder. I tried adding more Solder but didn’t work that well. Can somebody guide me and Brad in right direction…..Much appreciated.

Thomas

i tried using a toothpick and it got most of the solder away and made sure that the toothpick could go through the hole. you might have to wither the toothpick a little so it opens up the hole while heating it up. once the solder gets soft the toothpick should be able to poke through the hole

Steve

Does anyone have reviews of repair sites for the dc plug. I’m just going to send mine in to have it fixed.

Nur Hafiz

I’m having similar problems with my Compaq Presario M2000 notebook too. I had to wiggle the adapter to the power connector of the notebook or my laptop battery won’t charge and won’t turn on if it doesnt have it’s battery on. That metal thing which I plug into the DC gets extremely hot very quickly in matter of minutes also.

I’ve been looking for information on how to dismantle my notebook to get access to the DC power jack but looks like there’s too much risk involved. Too many screws to look out for and thin wires in the way. Almost made me feel like Im defusing a bomb or something. Im a college student living on college budget and couldn’t afford to buy a new laptop and the warranty is already up. I bought the laptop only 2 years ago.

I would really really appreciate it if anybody could give me a guide on how to dismantle my laptop and get access to the DC power jack. I’s gonna cost me $120 if I were to send it to the shop to repair.

It’s hard to go to sleep without knowing what’s to come.

adam

I see a lot of guys in over their heads here.

Guys, like said in the article, don’t do this if you’re not familiar with soldering techniques.

Pick up your phone book and find a local computer shop (NOT a box store, but a shop that does real repairs). Ask them if they do DC jack replacements. If they say “huh?”, hang up and call the next guy, until someone knows exactly what you’re talking about. Plan to pay $75-175. It’s a 2-3 hour job on most models.

cj2600

Nur Hafiz,

Here you’ll find links to HP/Compaq maintenance manuals. Find your laptop and download the maintenance and service guide, you’ll find step-by-step disassembly instructions in there.

Toasty

I would like to say thank you for this guide. Before I found this I was about to give up completely.

you see, recently, the power pin connector bent backwards inside my laptop and I had to leave the ac adaptor plugged in all the time to prevent the module from bending back in from re connecting the adaptor. Even more recently, the adaptor was knocked loose on the corner of the desk and the power pin broke completely. since I have had no experience replacing parts in the past, I tried looking for replacement motherboards, or alternate ways to power the laptop, but that didnt work out well.

The laptop, by the way, is an HP Pavilion ze4240

now I just need to collect the rest of the materials and a new power jack and I’ll be set. thanks again

Harry Stanley

Greetings from Scottsbluff, Nebraska …. Thank you for this wonderful advice and instruction. Harry

supa

thanks for this write up. I sought out a repair shop, but the ones that I called said they would not do it and referred me back to dell. they were lookin to charge around $200 bucks for the repair. I only bought the machine for $350 so it didnt seem worth it. This guide provided the extra look that I needed to do the repairs. thanks

Nick

Thank you for the tutorial. My gf’s HP notebook wasn’t working anymore and the little power symbol would only briefly flash when you stuck the jack in. I researched and assumed it was the same common problem and came across this site.

Taking apart the notebook was a bit of a hassle though I got it all apart, bought a solder iron and solder and a magnifying glass and seen that the back pin wasn’t making a good connection with the motherboard. I tried to solder it and then solder sucker it off, but that was futile. Also since I have never soldered before it was a little harder then I thought though I suppose a smaller tip would have made it easier. So I just put fresh solder all around the connectors, used some epoxy to hold the jack on a little better and put the notebook back together.

Everything is working great, and I saved $175 which the local shop quoted me. And best of all, my GF leaves my computer alone now!!!

PinoyEngineer

Tried this on my A70 and it worked! The disassembly guide is very accurate! Thanks and more power.

P Swinson

Hi,

I had the dreaded intermittent DC connection with an old Tosh Tecra 8100. Seemed a lot of hassle to strip it down completely so I very very carefully “dremeled” or milled a 1/4 inch rectangle of fthe bottom of the case where I reckoned the positive pin solder point to the PCB would be. Sure enough, exercising the connector had caused the usual, the soldered joint had failed. Remade joint thru the created hole. Then covered up hole with tape. I could glue something more substantial on but it is fine as it is. All working now for bout 10 minutes effort

cheers

Peter (UK)

Aamir

Thankyou so much …You made it so easy… I saved $$ ….really appreciate it… keep up the good work… now my laptop is up n running better then ever. Thanks Again.

sam

hi,

thnaks for this guide

but i’m having a serious problem after adding some solder to dc jack contacts . in facts i fixed power problem (battery charges normally but laptop in no longer booting

we could hear fans but nothing after black screen.

surely is not screen problem i noticed it’s ok when i increase brightness.

i’ve tried also by removing one of memories but nothing.

i’m sure that i’ve damaged Nothing in the mother…

could you nhelp me please.

ps: my pc is toshiba satellite p20 s103

DAVID

I’ve got a Toshiba Satellite A35 series laptop that needs a new USB port (one of the two ports broke). Do you have soldering and replacement instructions for this component? Thanks.

Ksideshh

Do you have to go through all 25 step of disassembly to perform the power plug replacement? Thanks in advance for your help.

K

the file clerk

o dear pitty thank you its actually functining now (although i may have killed my internet card in the process….) thanks though !

C Tobin

Just can’t thank you enough for the beautifully lain out guide. I actually received a Toshiba Sattelite as a “hey if you can fix it it’s yours” type deal. Lucky for me I found your guide first!

Thanks again,

C Tobin (USA)

Rob

When I plug my power adapter in, the light on the front of the laptop comes on for a second then shuts off. It will keep doing that if I pull it in then out. Is that most likely a bad connection with the power jack? or something else? Thanks a lot.

cj2600

Rob,

1. Can be bad power adapter. Test the laptop with another good adapter.

2. Can be loose power jack.

3. If not 1 & 2 then could be bad motherboard.

Bob

This is exactly what I have been looking for. The problem with the laptop I have is the middle pin broke out of the DC connector. I see there is a work around to remote the connector but do you know where I could get a replacement connector that I could solder to the motherboard?

Rob

I tried a brand new power adapter. I’m going to see if I can resolder the power jack now. I hope it’s not a bad motherboard, it’s probably not even worth buying a new motherboard with laptop prices going down so much. Thanks for your help.

Rob

I’m in the process of resoldering the power jack. Is there any way to test if it is powering the motherboard without putting the whole laptop back together first? I have a volt tester if that helps. Thanks.

Greg Ritsul

I am trying to resolder the power jack to the motherboard on a Vaio PCG-GX600 notebook. Only one little problem – I’ve removed every screw I could find on the exterior of the case, but still can not open the notebook to access the motherboard. What am I missing here??!! Toward the front of the notebook, it is reasonably loose (I could separate the top and bottom halves of the case without too much problem), but the back halves of the case are firmly sealed. Yet I can’t find anything else to unscrew to loosen that area.

cj2600

Bob,

It depends on the model of your laptop but most likely you can find it cheap on ebay.

cj2600

Rob,

Yes, all you need is three main parts: motherboard, CPU and memory. If the power button is located on a separate board, then you’ll have to connect this board too.

Assemble everything on your desk, connect an external monitor, plug in the power adapter and turn on the laptop. If everything is OK, it will start and you should get video on the monitor.

cj2600

Greg Ritsul,

I tried to google for PCG-GX600 and the only one site pops up, it’s my site with your comment. 🙂 Are you sure PCG-GX600 is correct model?

I posted links to some Sony Vaio manuals (including disassembly instructions) here. It’s possible that you can find model similar to your Sony.

JulieAnn

You are an absolutely fantastic human being! I’ll be using this over the weekend to try and repair my sad little Dell Inspiron 2200. Thank you thank you THANK YOU!

Bobby Reed

Nice tutorial, great pictures and instructions. Will bookmark, and use when needed!

bernie

Hi there, thanks for the advice. I took the lazy way, cleaned up all four solder points with a screw driver. Soldered all joints and bingo all working 100%, pity I bought a battery and adapter first. Great site.

jamie

nice gonna go buy a soldering iron now for £5 :D, hope it works well as nothing will oot on my computer ^^

Ron Buechler

Many thanks for the very clear and detailed instructions. Without them, I could not even have disassembled this overgrown calculator!

One question – is there any other source for the part other than ebay?

Best regards,

Ron

Randy

if this doesnt work, what else should i replace/repair to see if i can power up these two freebie laptops i have?

Toshiba Satellite A75-s206

cj2600

Randy,

Why did you replace the power jack in the first place? Did power LED flicker when if you wiggle the power plug or what?

Randy

yes, but nothing else.

I am going to find some new plug replacements and try again though, waiting for the mail man so to speak.

I got a slight orange blip of LCD light, then a red flashing one, then nothing.

Gary

Looking at this tutorial, it gave me an idea, i have soldered on at least 4 power jacks to my laptop(presario 2500), so i totallly dismalted it, took ou the old jack, and replaced it with wires heading directly to the power suppoly, because im not using this laptop for the batter functionality anymore, becuase 10 min doesnt get you far if u know what i mean, i just used a cheap 30 watt harbor freigh soldering iron, and the whole “repair” went smoothly. It took me a little over an hour to do it, but then again, this thing has been apart 7 times now.

Luke

Hi,

Great tutorial…definatly gave me some confidence boost :P. The laptop i want to repair is a really good one and i realise that if i don’t repair it, it will cost a bobm to get it proffesionally repaired, yed? So all im stuck on now is how to correctly dissassemble the case and also how to correctly SOLDER! Does anyone have a link to a useful website about these two problems (no offence). Ok thanks alot anyway,

Luke.

cj2600

Luke,

I posted links to some service manuals here. You may find your laptop in there.

You cannot learn it from books. Only if you practice.

Drew

Thanks for the pictures!! It helped out a lot.

Chris

Hi am in the process of doing this with my presario 2500. I was unable to cleanly get the power jack off so there are still pieces of metal in the holes in the motherboard. I was wondering if you had any suggestion as to getting this metal out? My new power jack is coming in the mail soon so if anyone has any suggestions.

Tom

Thanks for the pictrorial instructions they have helped me tremendously. I must say though, removing the old jack and cleaning the terminals is a lot more difficult for the unskilled than you make out, especially the positive post (or the one furthest from the edge) there is very little solder to anchor to. Nonetheless, I am thankful for your instructions.

I just hope I can put all the straps and screws in the right places. No doubt I’ll have one or two over.

jose

Hi,

I have an ASUS notebook with the following problem:

The notebook only works with battery power.

As soon as I turn ON the notebook, and the external power is connected, the notebook switch automatically over to battery power. It does not work anymore with external power. I cannot use the notebook with external power anymore.

The problem appeared when an other external power supply adapter (not from asus) was connected. The polarity os this power adapter was inverted, so something inside burned out.

Does anyone have an idea what could be damaged in the power circuit line?

Thanks a lot

cj2600

jose,

did you test the power adapter? Maybe this adapter is bad? You can test it with a voltmeter, make sure it outputs correct voltage.

Also, make sure your new adapter matches laptop requirements. The adapter must output the same voltage. Amperage on the adapter can be the same or higher.

Dave

I did this over the weekend, and the jack is coming loose again. I admit, I didn’t try to work solder onto each side of the holes, afraid of plugging them as others have mentioned. But, it’s already coming loose again. There doesn’t seem to be enough for the solder to grab onto to make a strong mechanical connection. I’m considering super glue for the mechanical hold, and soldering for the electrical connect. Anyone have better ideas or comments?

Dave

Follow-up. Cleaned up the board, burnished the contacts on the port, and drew solder down them so that it looked like they were twice as long as they were. I smeard the bottom of the port with 2-stage epoxy, put it in place, and clamped it in place with a spring clothespin. After it had cured an hour, I hit the solder on the contacts with my soldering iron, so that it melted down and formed a good contact. Using a toothpick, I worked a little more epoxy around the front edge, and not the whole thing is set up like a rock!

Sheri

Hi. How do you know when you have to replace the DC jack or not. The center pin which goes inside the jack is a little loose I can feel it a bit. Should it be replaced or is this normal? This is the second time I tried to fix this. I admit I did not take out the jack the first time but just took off the old solder and put new on. It worked for awhile but then got loose again. I didn’t see my power lite come on at all just the battery and the ‘on’ lite. Why is that? Should I be using some sort of glue as well. I noticed that there was some on it.

Josh

I have a compaq presario R3000 and have a power jack issue and it seems that it just becomes unsoldered everytime i repair it although i’ve never cleaned the surface after removing the jack. Coul that be why or is there another explanation for my problem? Please let me know some ways to PERMENETLY fix my problem.

cj2600

Josh,

That could be your problem.

In order to fix the power jack correctly, you’ll have to:

1. Remove the power jack and clean contacts on the jack. Apply some fresh solder on contacts.

2. Clean up contacts on the motherboard and apply some fresh solder on them too.

3. Solder the power jack back on the motherboard.

Brian

Hey guys, I too am having difficulties removing the DC jack from my Dell D600. The jack itself looks like ti has 4 prongs that are affixed to the motherboard via glue and 5 points that are soldered in.

Picture – http://images.marketworks.com/hi/72/72457/dellside2.jpg

My question is what is the best way to remove a jack that is glued and soldered in? I don’t want to apply too much pressure to damage the motherboard.

Brian

Nevermind i got it

mr. john king

hi, ref. DC Power jack.

when you move power cable, the power cuts out,

should the battery not kep pc running?

my laptop dont power up at all, but the blue power light on the front flahes 2 times,

so i am not sure if this is my problem

( HP Pavillion ze4800)

any other ideas?

George

Thanks for your steps. But I ran into a problem trying to coat the holes for the jack on both sides of the board. One of the holes got blocked with solder. How can I recover the hole? One of the pins of the jack need to go in there. Thanks

cj2600

George,

Apply some fresh solder on the hole, heat it up with the soldering gun and suck out the solder with the sucker.

John Richard

Hi, I have Toshiba Satellite M35X laptop. I replaced the dc power jack as described in your instructions. Everything worked fine. The power works now. The problem is I see nothing on the screen. It’s black. I put everything back the way I took it apart. Can you tell me what I did wrong and why I can not longer view anything on the screen. Thank you for this site and your help.

Warmest regards, John Richard

Joel

Fantastic walk through! I used this for my HP ZD7000. Ordered a 10$ DC plug from a guy on e-bay. Don’t get ripped off by going after the 25-30$ parts. Took my time working my way around the connectors desoldered the old one. Drank a beer to calm my nerves and continued on. Cleaned it up and put the new one on. Good as new. Only thing… I have about 50 screws left over. You think they really need this many fasteners to hold together a 8lb piece of plastic ;-)? Many thanks and again great walkthrough!

cj2600

John Richard,

Did you test the laptop with an external monitor? If you have no video on both internal and external screens, make sure the memory module is seated correctly.

If external monitor works fine but you have no video on the internal LCD, check the video cable connection on the motherboard, make sure the cable is properly connected to the motherboard.

brian

worked perfectly, thank you so much.

i originally thought this wouldnt fix the problem i had (having to hold the power cord in to charge the laptop) because on the outside the jack didnt seem to have any damage. im pretty used to soldering componants, usually much smaller than this, even though ive never worked on laptops before, so i figured the worst that could happen is i unnesessarily clean up a connection, so i went ahead and did it.

well it ended up being the problem, and this fixed it. once i opened up the laptop i found the jack itself had melted all over the place, and onto the contacts, so it was def in need of changing. the 4 prongs seemed to be making contact, but i guess the oxidation and melted crap was deterring them from being very good conductors.

John

hi, is there any way to remove the solder from the mother board without a pump, as i don’t have a pump. 3 2 of the four holes are blocked and i need to put the new DC power jack onto the motherboard? Any suggestions?

headborg

Hey, I found your “how to” instructions very useful several times- yes, I was a sucker for buying a toshiba a75. Now I have a related problem- the little black resister? next to the dc jack- labeled CH4h SS14 — it has poped/overloaded– I’ve called around and even taken it into Computek- Springfield– and no one seems to be able to

help me– surface soldier a new one in place– and I’d like to try it myself- but I need to find the component- would you know where I could find this part? And how difficult would it be to replace it? It appears to bridge over to the chassis ground?

cj2600

headborg,

Sorry, cannot help you with that one. All my soldering knowledge is limited to power jack replacement. 🙂

Bruce

Have compaq presario 1610. A tech who tried to fix it says dc adapter pulled away from traces and can’t be fixed. Maybe a dongle can be added further down the line as a work around. Anyway, need help finding dissassembly instructions. Tried your link but it takes me to a maintenence manual that is about cleaning, travel packing, but no dissasembly instructions. Thanks

cj2600

Bruce,

Not all HP manuals have laptop disassembly instructions, I believe only newer models have it.

brian

how do i check if the mother board is fried or if the jack is fried???

Chris

John,

Solder wick. Its copper colored, sometimes its called solder braid. Comes in a roll and is fairly cheap.

Headborg, check out Fry’s. Its an electronics store, to get a cross reference you might try a company called haystack.

Brian, you should be able to check continuity through the input jack that connects to the mobo.. Most voltmeters have this function available.

cj2600

Brian,

1. Test the power supply itself. Make sure the power supply is not dead and outputs correct voltage.

2. Take a closer look at the power jack. If solder joints have no cracks, the power jack is in a good shape but the laptop is completely dead, most likely it’s bad motherboard.

As Chris mentioned in the comment 98, you can check continuity with a voltmeter. If the motherboard receives correct voltage from the power supply, but there are no signs of life, apparently you have a bad board.

Andrew Smith

My A60 does not power p at all so i will try this method

as all that happens when i conect the power pack the pack starts to make this squeeking sound so im asumeing this is the problem I will post after i try this Thanx

kyak

i got a nec laptop the other day.it worked fine at my friends house,but when i took it home i think i messed it up,i forgot it was plugged in and i removed the battery while it was plugged in now it doesnt show any leds when i plug it up,do you think i fried the mother board or something,help me pls its a really nice lap top and i got it for free would love to fix it…

cj2600

kyak,

Try the following. Unplug the AC adapter, remove the battery, wait for 2-3 minutes. Install the battery and plug in the AC adapter. Try turning on the laptop.

Maybe the adapter is bad? You can test the adapter with a voltmeter.

SEMWANGA NICHOLAS

my laptop is just new and i hope to use the idea u have give mi.thanks.But do i need to replace a new jack for my laptop to work properly?the problem is that its jack port pin became loose.

David

I have a Dell Inspiron and had the original ac power supply burn out on it (no green light on the box, nothing on the voltometer) and found a third party adaptor that worked for charging. Then it stopped charging my battery and would not run the computer with the battery removed. No matter how much I wiggle it there are no flickering lights on the the ac indicator. I am in Taiwan where there are no Radio Shacks and only one Dell store (in a different town). I don’t have a soldering iron so it is in the repair shop and I have them looking at the power jack but I don’t hold out too much hope since I had no flickering lights. My question is there a way to make a standalone battery charger so that if my motherboard is fried (still runs the computer) that I can just charge the batteries seperate. Due to an error in shipping Dell sent me three batteries instead of one so I have plenty to charge and keep me in power. I would be interested in this even if I the the problem fixed.

Thank for the help and sorry for the long post

Desperate in Taiwan

Quophi

Anytime I turn my laptop (hp dv 1000) the battery led is on but the machince wiil not boot.Explain to me what i can do to serve my machine

cj2600

Quophi,

Could be memory related problem. Try reseating memory. Move memory modules from one slot to another. Test the laptop with another known good memory module if you have it.

Tony

i have the Toshiba A70 laptop and the AC adaptor is not charging my laptop. i know theres a problem with the DC not connected to the motherboard right. so i took apart my laptop and try to solder it myself. when i’m finishe i plugged the AC to my DC and get this burning noise coming from the DC then it started to smell like sometings burning.

Did i short circuit something? if so, is it possible to fix it or did i fry my motherboard? i can still turn on my computer fine just not with the AC adaptor plugged. should i buy a new jack?

Kish

I have a M35X-149S Toshibha laptop, currently ot does not start. Does this laptop have a problem with DC jack? Yesterday, while i was working monitor screen went blank, however, power light was on. I tried to turn it on and off to see if I could see any display but without success. After a while, even power switch stopped working. Now it is completely dead!!!

Does this laptop has motherboard problem or power (DC) jack problem?

Thanks for your help.

Krish

cj2600

Kish,

Can you see any LED lights on the front when you plug in the power adapter? If the power LED lights up but the laptop will not start when you press the power button, there could be a problem with the memory. Try reconnecting the memory, move the memory module into the empty slot.

If there are no LED lights, check the power adapter. It has to output 19VDC.

Kish

thanks for your advice. i tried what you suggested, but it did not work. the laptop is still dead. the power switch still does not turn on the computer, and there are still no lights and no response. i also checked the power adapter, and it did show 19VDC output. do i have to take apart the laptop and look for defects in some hardware (like the power jack, etc)? what are my options here?

thanks again

cj2600

Kish,

If the power adapter is fine then either there is a problem with the power jack or the motherboard is dead.

It’s necessary to take a closer look at the power jack. When the motherboard is removed, you can plug in the power adapter and test if power comes to the motherboard. It’s possible that you have a blown fuse witch is located close to the power jack. It’s possible that you can fix the laptop by replacing the fuse.

If the fuse is OK and motherboard receives power from the adapter but the laptop is still dead, most likely you have a problem with the motherboard.

Icydude21

I just want to say thank you soooooo much for posting this guide and helping us with this problem. I have fixed my laptop after it has been sitting in my closet for 2 years. I have tried multiple times for the past year to try and solder the power jack back on properly, but I was just not able to. Your guide, and the comments, and your responses all helped me to do it finally today and I am really really thankful and happy.

The main problem I was having was with actually soldering the power jack onto the motherboard. I still have not soldered it fully and properly, the solder is only sitting on half of the joint for each of the joints, but it is the best I could get it. The laptop is powered again, so hopefully the joints will last a long time.

Is it okay that the joints are only soldered on partially? Will this cause any kind of problem if I continue to use the laptop like this? Or is the only problem in doing this that the solder is more likely to come off again? Thanks again!!

cj2600

lcydude21,

I think you can use the laptop like that but I’m not sure if your soldering job will last forever. 🙂 Be careful when you plug and unplug the power adapter.

Gary

Is there any way to figure out where the screws go if you did not label them? It is an Acer Aspire 1640. The repair manual does not tell you this.

JT

Can you tell me where to find a replacement DC-In for an HP DV8013CL?

Jamie

This is an excellent guide, many thanks for taking the time to document your work.

JP

Thanks for the informative site…the pictures are great too. Here’s my problem: I installed a new jack in my HP Pavilion ZE4900. When I barely insert the power tip into the jack, just making the connection, I get power. When I completely insert it, I lose the power. I looked at the design of my jack from the rear, and when the tip is fully inserted, the (negative?) plate or “tongue” inside compresses down, which looks normal, but it looks like it disconnects from another contact above it. Is this because when running on battery power, that completes the battery’s circuit? If so, I suppose my solder of the negative plate is bad?

Lukh

Hi,

I just want to say: “THANKS ALOT”.

i have a Toshiba A70 Laptop and the power adapter needed to be replaced. I took it to the computer shop and the guy coded me $240.00. I could not afford it so I stop using that computer. but few days back i found this site and i fixed my computer, resolder the jack, and also clean it from inside. With the help of all the pictures I found that it was not that hard. so thanks alot guy. thanks alot.

regards,

Lukh

Faby

I need help!!!! My notebook laptop won’t charge. I was told that it was the DC adapter. I don’t know anyone who knows or does this. Do you??? If so, what do you charge???

Jason

In this guide, you used / repaired the DC power jack that was originally from the laptop. Correct?

I am buying a new DC power jack, so I do not have to “clean all oxidized contacts with a knife” or “apply a fresh coat of solder to all contacts on the power jack”.

Also, I do not have a de-soldering pump, is this tool necessary?

Ann

My power jack broke off so I replaced the jack and soldered it on firmly. Now the power only comes on if I hold the power adapter in firmly. Did I do something wrong?

cj2600

Jason,

No, it’s not necessary to clean contacts on the new jack, it’s ready to be soldered on the motherboard. You’ll have to clean contacts on the motherboard.

This tool will help you remove the old power jack.

cj2600

Ann,

Make sure the jack is soldered properly. I cannot tell you what is wrong without looking at the laptop.

Moa

I’m also a repairer like you. An hp dv9000 laptop powers up with dead screen and after 20 sec again reset. This loop happens for ever untill I power off the system. Screen is dead. Does it belong to graphic chipset? I tried external monitor, again no screen. Only reset and reset after 20 sec.

gerald

Help! I have a Presario 2500. Once I’m in Windows XP the power shuts off at random. When trying to re-install XP the power keeps shutting off during the install process. There are times, where, I’m in XP desktop and the laptop is on a firm table, the computer will run for hours (with A/C power plugged in). Then, if I sit on the sofa with the laptop on the cusion, it shuts off in XP only after a few minutes. I ran a temperature program which only showed a yeelow flag warning on the hard drive at 56 degrees celcius. Sometimes I have to wiggle the A/C cord to get the laptop to come on. But I’m not totally convinced that the A/C power connector is totally at fault. Is there software that will check the memory, and hard drive? Is there software that will let the computer run without a windows enviroment? thnk you.

cj2600

gerald,

Your laptop shuts down because of overheating. You must keep the laptop on a flat surface. Apparently, there are cooling fan air intakes on the bottom of your laptop and when you keep it on the cushion, the air intakes are closed. Without air circulation inside the heatsink your laptop overheats and shuts down.

cj2600

Moa,

Here’s what you can try in order to troubleshoot the laptop. Disconnect the LCD screen cable from the motherboard. Minimize the laptop as much as you can. Remove hard drive, DVD drive, wireless card, unplug the keyboard.

In order to start any laptop you need only three parts: motherboard (I assume the video card is integrated), memory and CPU.

If the laptop still doing the same thing, most likely you have a problem with the motherboard.

Stew

Laptop Toshiba A30 would not charge while running and the battery was going dead in about a 1/4 of the usual time. Lights flickered when plugging in the power jack. Took it apart and re-soldered. Worked well for 2 days. Turned it off and left on power supply over night. Next morning the laptop would not boot. Press the power button and all sounds good for 4 seconds then the fans stop and it does not boot and the power light stays on but the hard drive light never flickers during this process. Then realized the power supply had burnt out. It must have been trying to boot from the battery. I believe the positive pin of the power connector must have eventually shorted thus burning out the power supply. I have two of these laptops so I tested the cpu, hardrive, in the good laptop and they worked fine. Took apart the laptop and could see an indication of a short next to the positive pin of the power connector. I believe the pin shorted on the corner of the silver grounding of the female video connector located on the M-board. So I now have a couple of questions.

1. Is the positive pin supposed to make contact on both sides if the M-board or only one side? If yes do you solder both sides?

2. Are there several layers of tracing on one side of the circuit board or is there just one on each side.

3. What other steps to trouble shoot can I do?

Clearly the positive trace on both the cpu and other side of the positive trace connector for the power input is still shorting to the ground on the video connector even though I have removed the power connector. Things are looking a little messy even with the great care taken. I am considering to take a sharp exacto knife to go around the area of the video connector corner where I believe the positive pin traces are shorting, to sever the short. I don’t believe there are any traces there but not positive.

Any feedback or comments from the pros would be greatly appreciated. (Toshiba A30)

Thanks in advance for your comments and help!

Stew Lockhart

Alan

Hi

Followed your instructions for taking the Toshiba apart and fixing a new power socket everything has gone well until I have tried to re screw on the screen, the hinges seem not to want to turn so I can’t re screw in. Its a Toshiba Equium A60-181 and I was following the guide from the Sat A65 which as near as I could find.

Very frustrating not being able to complete rebuilding to check out my handwork Can you help please. Cant see why the hinges will not turn logic says they must!!!!

Regards

James Bayliss

Hello, thanks to your instructions I have managed to fix my wife’s ibm thinkpad 1200 which I dropped 2 years ago! Unfortunately during the soldering I broke off a component which looked like a resistor and it pinged across the room, never to be found. I think that it was part of the battery charging because the battery doesn’t charge now but it wasn’t any good anyway so it will be used like a dsktop.

Thanks again for posting all this useful stuff, I might have a go at the photo frame next with an ancient laptop of mine!

elizabeth white

Hi there, already done youre step by step instructions and the laptop still wont charge or even switch on. I really am stuck now! Please help!

cj2600

Stew,

Usually it makes contact with both sides. There is a sleeve inside the hole for the positive pin and this sleeve connects traces on both sides of the motherboard. You should solder the positive pin on one side of the motherboard but traces on both sides are connected by the sleeve inside the whole.

From my experience, Toshiba laptops has only one layer of tracing on each side of the motherboard.

Maybe you should try resoldering the power jack.

So the laptop actually gets power but will not start? That could be memory problem. Did you test memory in second working laptop?

cj2600

Alan,

Not sure what could be wrong. Are you trying to turn hinges with your fingers? It’s not easy!!!

First, install the screen back into the place. Second, rotate the screen so you can access screw holes. It’s way easier to rotate the hinges when the display assembly is installed and both hinges are secured in the laptop base.

cj2600

elizabeth white,

How can I help if I don’t even know what was wrong with your laptop and what you did?

don

I resoldered my jack as explained, but with a meter I read continuity between the center pin (I assume the +) and one of the other pins (the outermost pin). Is this normal or do I have a direct short? I obviously don’t want to fry anything! Thanks!

cj2600

Don,

Something is wrong. Apparently you bridged traces with solder. Take a closer at your soldering job. Do not turn on the laptop like that or you’ll fry the motherboard.

Karl

I need a way to source the generic connector name for the male dc power connector that plugs into a Dell Vostro 1400. I’m referring to only the actual plug on the power cord NOT the entire power cord itself.

THANK YOU very much for your assitstance

Vivienne

I have a question about the power jack, do they have a positive and negative points? I soldered a dc power jack on a sony laptop but there was no indicator for + or – side. Ive tried testing the power jack but I cannot tell if its right, I dont want to short or fry my laptop.

Bob

It can only go in one way, unless it’s wired

Vivienne

This particular DC jack can go in several different ways. If it only went in one way I would know.

Brad

Worked Perfectly! A nice $10 repair. Thanks for the great website!

marcelo

thanks… its really work… thanks a lot.. at least i repair my lap….

you are so explicit and clear…

best regards..

marcelo

Steelgod

Amazing.. it works ! Simple, direct and useful .

Thanks a lot man.

Sanjay

HI I have a HP Pavilion ZV5000 and the power jack has been repaired. The laptop worked for a while then it stopped working and the little light on the power cable transformer is lit before i connect it to the laptop but as soon as I connect it the little led goes out and the laptop does not fire up. What do you think may be causing this?

Many Thanks

Sanjay

cj2600

Sanjay,

It’s hard to answer this question without testing the laptop. Here’s my guess.

1. Possible poor soldering job. Maybe the power jack is broken.

2. Bad power adapter.

Anil

I have an acer with charging problem. I have tried resoldering the old power jack (having removed the old solder) but to no avail. I am planning to replace the jack but I have noticed that this jack has been stuck to the board with some sort of resin (glue?). I am wondering if it will be possible to remove the jack without damaging the board. Any suggestions for removing the resin (glue?) to get the jack out will be appreciated.

Rob Meyer

I replaced my dc jack and I tested the continuity and it beeps on my meter. But when I plug in the AC Adapter the led on the adapter goes out and get no power. I have to unplug the adapter to get the led back on. The AC Adapter is good because I charged my other laptop just fine. Why does the led go out and not charge my laptop.

Rob Meyer

I plug in my apapter and i seen a spark on the dc power jack is this a short and can it be fixed.

Jesse

Thank you very much for your tutorial. Although not an easy process, it was successful and saved me over a hundred bucks in repair costs! Keep up your good work!

Mike

Hey Cj..

Thanks for the illustration.. I have completed everything and reassembled. The laptop isnt recognizing the jack i installed or something. All pins are soldered nicely. However, I did not pay attention tto the “sleeve” on the positive pin. I did yank it out :/. Should have read on before pulling .. its a new jack from ebay as well. looks like the same one used in this article. any suggestions would be appreciated

Mike

Mike

resoldered the old jack back on and works like a charm..

let me clean out my heatsinks and fans too.. they were nasty

Thanks for the help!

if i followed the first instructions i wouldnt have needed to buy the new jack 😉

Mike

rod

what is the orange/amber color on the motherboard where you apply those solder coat? what happens if that orange/amber color got removed while desoldering?

ivan

have same problem , but dont have power jack on motherboard

pls email me and send you pics

Martin Sheldon

Rob Meyer it sounds like u have a short on the board, the boards are multilayered and have tracks inside the board. Did you notice any damage to the power jack area, was any of the power jack contacts on the board black or crispy? if so then its likely that this is where the short is and its terminal, new board required. If not then its likely to be a faulty IC or something on the board, if nothing is obviously damaged on the board like a burnt/crispy chip then its probably a faulty IC shorting. This guide is good, I’ve been doing jack repairs for a few years, the only thing I would suggest is never use the old jack, if the centre pin is loose then its likely to be damaged and will more than likely work loose again, always use a new jack, they only cost a few quid from ebay!

Robin

Thank you for your help on the DC power jack as well as taking the whole thing apart , that was not easy. Now I’m afraid putting it back together is going to be a bigger nightmare for me , I would appreciate any and all information that would benifit the reserection of this master piece.

Ron

Good advice! Everyone should read the part about the sleeves through the Mb,Very Importaint not to Damage the board.

Rob Meyer – Sounds like you have a bad Mb. Thats a short condition on the DCV.

I have the same Jack problem as so many do, Glad I found this. The service Manual is on Dell and works through your web browser. Thanks for the Detailed Steps. Going to have fun fixing the laptop.

Nathan

Hi, I was just wondering if you might be able to add a little thing about how to match the DC power jack to the barrel of your AC adapter in the case that you need to replace the DC jack.

The weird branded Enpower Laptop that I had to replace the power jack for doesn’t have a part number I’ll see if I can’t find it though. Just need to find a workable DC Jack that’l work with a LSE0202A2090 AC Adapter. 20V, 4.5A 90W Max. Looks like a 5.5mm barrel. I could be wrong though.

livi

Hey i’m pretty sure mine has broken, i asked at the shop about it and they said it would cost £200 to repair -___- now that isnt far from what i paid from my lappy haha! is that amount accurate? because ur guide made it look not too hard (not that i would ever atempt it myself)

Jim

I can’t seem to get the last bit of old solder out in order to push the pins on the power connector through the motherboard. I am using a vacuum desoldering bulb. Any other ideas?

Thanks

Jeff

I have a Toshiba A65-S126 and Iafter desoldering the five contacts of the DC jack using a pump and wick, I still cannot remove the Jack from the Board. What am I doing wrong? anyone have any good suggestions? this is a five pin DC jack and know matter what I try it just will not come off.

T Moore

I followed all these instructions and my A70 is now working again and no longer destined for the scrap heap.The only thing that you should do in addition to these great instructions is note where each screw goes as some are different lengths and I put the wrong one in one area and my DVD player would not go back in place as it protruded through the motherboard.I am no electronic wiz but will have a go at most things and for $40 australian for a new DC jack I am all up and running again and it was no too difficult.

Jim

Toshiba, M35X

Thanks, I found your instructions easy to follow and I found that the problem was a little more then resoldering the jack. I have ordered a new jack and will install it when it arrives

JKay

Thanks a lot for these instructions!

For $4.50, I saved my Dell Inspiron 6000.

A couple of things for those who might find themselves in the same spot, on the same laptop:

1) I could _not_ get the darn thing off. I finally snipped it in half, longwise from where the ac adapter plugs in, with a pair of wire snips. 🙂 Not for the faint of heart….. I imagine the right thing to do would be to be patient and not do something crazy.

BUT…I did it, and it made it much easier to pull it out, one-half at a time. Just use a pair of needlenose on the half-piece, apply heat and voila.

On my first attempt I reassembled the laptop only to find the same “ac adapter not recognized” message. I disassembled all the way down, heated up the iron, and took a second look at the middle pin, furthest from the adapter opening, the one that carries the voltage back (19v?) and tells the laptop that you have a genuine Dell adapter. Sure enough, I hadn;t gotten a good solderpoint. Heat, more solder, reassemble and sweetness.

Thanks again for the great instruction!

CRN

Thanks to this article, I saved my HP ZD7000 from the scrap heap! Fixing it with a replacement part bought from Electronomax on ebay, I was able to replace the DC jack with little effort. Unfortunately, I should’ve documented my screw removal a little more carefully as I ended up with about 6 extras screws after reassembly, but everything else feels solid and I did it myself!

ric

after i resoldered power jack the led lights were flickering. what is that a sign of? loose connection?

charasoverride

you are a crack!

thanx for this wonderful tutorial!

nick

if you find that the scren still flickrs it may be the pin insde the power supply s loose… relace the unit on te motherboard alltogether that should do the trick

Whohlme

Hi,

is it possible that I use a small de-soldering bulb from radio shack, or should I get the elongated one that you use? Thank you.

cj2600

Whohlme,

I think so. As long as it works and you can remove the solder with this bulb. I haven’t tried it myself.

Whohlme

wow! that was a fast reply! Thank you. I read a general soldering site and it said bulbs are good for general purpose work but the pumps have more suction power and make things easier. I got the bulb for Christmas, but since they are roughly the same price, i may exchange one for the other.

Also, would a solder accessory kit be worth keeping? It has heat sync, brush, and probes. Thanks again

Louis

The solution to my problem on the very first page of the first site I visit. Must be a world first.

David

Hi,

How am I suppose to resolder the connection at the same time follow the assembly steps on this page?

R/

David

cj2600

David,

I guess you’ll have to have a second working computer or print the guide. 🙂

dezz

After following these instructons, my laptop now charges but my screen now won’t come on and the pc shuts down shortly after i turn it on. Any tips??

CB

Laptop repair guy do you have a degree in engineering or something cause the content on this site is excellent !!!

Geri

Replaced the AC Jack in my Dell Inspiron 5150 and when we plug it in the right and the left front green LED lights are flickering rapidly. The middle one does not come on. We checked the adapter and it’s sending 12 volts fine. Any suggestions?

Caz

Laptop dc in jack repaired many thanks, I can not get the keyboard strip back into place it is very difficult as it sits under the motherboard,

PACKARD BELL EASYNOTE

can you provide any suggestions.

thanks.

Yesenia

Can I use Silicone Grease instead of Thermal Grease to put on the CPU?

Jose

After following these instructons, my laptop now charges but my screen now won’t come on and the pc shuts down shortly after i turn it on. Any tips?? could it be my CPU?

Jeff

So my Dell Latitude D505 showed all the symptoms of a failed dc power jack; so I took it all apart down to the motherboard and then took the motherboard to a laptop repair shop to have the power jack resoldered. After putting it all back together the computer still has no power.

1. Is this b/c the battery is still completely dead?

2. Bad Motherboard?

Any suggestions from this point would be greatly appreciated.

Dave King

On the picture where you see the pads you want to do more than just desolder and stick the new jack in. The offical Toshiba fix is to do this and then run a bead of hot melt glue around the connector. Thats a little better but will eventually work loose.

The trick to fix it so you can forget it is to scrape the entire pad free of the green coating (solder mask). Then insert the new connector and tack it in place with a small bit of solder on each pin. You do this so you get the position right. When you have it in place solder the entire pad. It will take a bit of solder but when you have it soldered you should have a smooth solder layer with the tips of three pins sticking out. Normally you don’t use anywhere near this amount of solder but in this case we are using it to provide mechanical and electrical strength. Not exactly what solder is meant for. You can also do the hot melt glue but its not required.

The problem or one of them with the Toshiba connectors was someone was a bit too tight on the solder mask around these pins. So the result is there is not much solder and the transition is too sharp from pin to pad. Normal use will crack the solder sooner or later and you know the rest. Scrape the pad and you have a bullet proof fix well until you wear out the pin ;-]

otho

hey ya all, i have a dell c640 that wouldn’t power up nor charge battery while pluged … i tried my battery on a friends computer and charged just fine… connected the dc adapter and worked aswell… i assumed that i had to change the dc jack on my motherboard , so i did and i still ha the same problem… it’s so tiny it’s a serious bi**h

what do you think the blem is ?

Jimmus

Hey, I use an Alienware Aurora m7700, and this guide really helped me fix the power problem. I would have to swivel and move the cord just to get power.

However, after I put it back together, my laptop got power, but won’t turn on. It charges, but when I hit the power button, it blinks all of the lights, and then nothing. It goes right back to charging. Any ideas?

Meg

I have a Toshiba Sattelite L355D and it’s a great computer but the thing thta pisses me off about it is that the DC charger is sticking out so much when you plug it into your laptop. So, yeah as I was wakling by a door entrance on wireless, I had bumped the wall with it ever so softly and it got loose. I got so upset but luckily it was anything real serious. The guide is great but I don’t think I have those things to fix it lol. I’m only 16, I’d probably murder myself with that thing by mistake. But, it looks very handy. Nice work on the guide.

Amy

Thanks for these instructions. In your opinion, I have a Dell Inspiron Laptop. The customer works fine, I’m not getting any error messages when using it. About two weeks my daughter knocked it off the computer table on to the back edge (where the power cord plugs in). The next day I was using it and realize that my screen had dimmed and that the power cord wasn’t being used only my battery. I continued to use the laptop for an hour or so, so I could finish up my project. Again absolutely no problems at all, internet was fast, programs loaded, etc.

In your opinion do you think this process you have provided will correct the problem?

cj2600

Meg,

I don’t like how the power connector on this model is designed either, it’s very easy to break.

In a Toshiba Satellite L355D the power jack is NOT soldered to the motherboard, it’s attached to a power harness.

In your case you either broke the DC-IN jack or the mounting bracket on the base assembly where the DC-IN jack is mounted.

If it’s just the jack, it’s necessary to replace the DC-IN harness.

If it’s the mounting bracket on the base assembly, it’s necessary to replace the base assembly.

By the way, it’s likely that you broke both.

Kyle Igantowicz

GHETTO WAY THAT WORKS!!!!

The peg inside my computer broke, and I was about to try to replace it, but if you like do things kind of ghetto like me, I discovered an option. First take out the broken peg if it is still in the end of the power adapter, and in is place, fit in 4 pieces of 2 inch long copper wireing. Then cut them all at once, just so the copper is only slightly coming out of the end of the power adapter. Does not work perfect, and you need to wiggle sometimes, but better than getting rid of the computer, or trying to fix when you have no experience.

Dennis

I have my Dell Inspiron disassembled but there is no physical evidence that the power jack is bad, Can I plug the ac adapter into the motherboard and test voltage and continuity with the motherboard removed from the laptop without causing any damage to the motherhboard circuitry?

Thanks.

Misha Koshelev

So I’ve disassembled my inspiron 600m and soldered on a new power jack. Unfortunately the service manual did not go far enough as far as getting access to the motherboard, so I improvised, but in the process of moving parts (off my bed, ok so I thought it might not take as long as it did) I don’t think I _quite_ know which screws go where in the parts that I did after I finished following the service manual. Any help would be appreciated.

Thank you

Misha

cj2600

Dennis,

Yes you can. You will not damage the motherboard if you know what you are doing. Sometimes, when I’m not sure if the jack is bad or not, I test motherboards like that. I plug the AC adapter, connect my multimeter to the solder joints on the jack and start moving the plug inside the jack at the same time looking at the voltmeter. If power cuts off when I move the plug, apparently it’s either bad connection between the jack and motherboard, or the jack is bad (I assume the adapter is working properly).

cj2600

Misha Koshelev,

Are you looking at the right manual? The Service Manual for Inspiron 600m explains how to access and remove the motherboard.

Ryan

I never thought I could pull something like this off, but it worked!!! Thanks so much for the step-by-step!!

altair

hi i have a compaq laptop . few days back due to some power fluctuation i laptop stopped charging . when plug in to the power i am getting the burning smell. so when i have read u r post i opened the laptop to check the dc power jack . my dcpower jack is covered with some plastic sheet . sheet under the dc power jack is fine . but adjacent to it has got burnt(just near one of the pin of the jack ) . now i am unable to figure out if there is any part that has got burnt out or is this due to dc power jack problem .

cna you please help me to figure this one out

leidiana frerichs

Hi, i have a tx1000 hp pavilion that got the lcd speaker connector is broken. that connector is the one in the motherboard. where can i get that connector? I know how to replaced it. please let me know the company where i can get that connector. i don’t know the part number to do the search.

please

Christy McStinkles

Amazing tutorial!! I’m in the process of replacing power jack on HP zv5000. Do these jacks have any copper connector on the jack? De-soldering was a bit messy and I have a piece of copper left over from something ( maybe a different project). It doesn’t look like a the plug shown in the pic. Thanks.

cody

I have a Toshiba A75. I took out the mother board and am looking at the power jack. My question is, are the 3 solder points in the middle of the jack all negative and is it ok to have one pool of solder to flow over all three? I saw a photo were the power jack was left on the outside of the laptop and just the wires were run into it and soldered to the mother board. The negative wire was soldered across all 3 of the contact points in the middle of the jack. Is that OK?

RobertM

Hi, I’ve run into a Dell laptop that seems to use different solder to connect the jack’s external case to the motherboard. It is a nine pin jack (3 rear, 2 center underneath, 4 casing pins).

All but the 4 casing pins desoldered nice and easy. The 4 casing pins (which, btw, are soldered on top and bottom) have solder that would not even melt using the standard guns (35W and 45W) we use for most repair jobs. Fun job. The “big” gun managed to melt it.

Wish I remembered which model (sorry, work on many of them a month).

Anyway… very secure jack in that model – sadly the customer dropped it while the DC adapter was plugged in, which shattered the inside of the jack.

Rami

Hi,

I had the same problem on my toshiba,

I did exactly as you show above, excep that I also removed the LF12A next to power jack and by mistake soldered it back in in the opposite direction,

A. what is this unit at all?

B. Can you please send me a photo simliar to the 2nd photo you posted from top. under the LF12A theres a PC1 typed on the motherboard, should there be any thing it seems missing on my laptop.

Thanks.

maria

Hi, I have a Toshiba Satellite A75-S209. I have tried to replace the DC jack, and it was successful for about 5 minutes. I attempted to boot up my computer and the repair turned out to be no good.

So the laptop was taken apart again. We have placed a meter on the DC jack and there is power getting through.

But we have placed the same meter on the small white rectangle with the funny L1 with a F in the middle and a 2A after (pictured in the second picture) does not have an amperage on the end towards the center.

I believe that is the part that needs replacing, but I don’t know what that is. Can someone please help me by identifying that part?

Thanks so much

Maria

Lisa

Hi all.. hey I have been working on this compaq m2000 for about 2 weeks now. I ordered a new adapter. I would like to know if anyone knows where I can just buy the whole dang peice. On this serie’s its on a separate power board from the mother board. I found 1 on ebay.. just one. I have searched all over for this thing. Its all attached and ready to place no sodering or anything. I have tryed to sodering and that didnt work, now I have the new peice and cannot get the one I sodered off lol.. ooooh my. The laptop was working just fine and this is the only prob… does anyone know where I can buy the jack board with the jack or without it I guess.

Thanks

Fran Rohm

I have a sony vgn-690, the dc adapter was broken I replaced the part, it had no soldering involved. It worked great for two weeks know the computer will not start once again. Is there anything I can do to chek the mother board. I just don’t understand why it would work great then stop working .

Cathy

I have a Dell Latitude D600. It can run on a 65W PA-12 (model HP-OQ065B83) or PA-10 (model PA-1900-02D, don’t know wattage) family of Dell adapters. Both models have input of 100-240v 50-60hz, output of 19.5v. PA-12 outputs 3.34A. PA-10 outputs 4.62A.

I normally hook the laptop to the PA-12 adapter. About 2-3 weeks ago, I noticed that the icon which shows if I am on battery, AC, or AC and charging, kept flickering between AC and battery power. Finally, it stopped charging the battery in addition to not powering the laptop. I figured it was a problem with the AC adapter. Luckily, I have another PA-12 at home. So, I started using it. Everything worked for a while. Then, the 2nd PA-12 adapter started to act the same way as the first one. I have a docking station which is hooked up to a PA-10 adapter. So, I took the PA-10 and used that to run my laptop. Again this worked for a while and then the same problem. So far, 2 PA-12s and 1 PA-10 had stopped working. Then, I took the docking station (luckily it is small), connected the PA-10 to it, and docked the laptop. Everything worked. But soon after, I started getting a message that the laptop is docked, but the AC Adapter type is not recognized, and to undock the laptop or use another adapter for the docking station. I took the PA-10 and hooked it back to the laptop and removed the battery. If I play/move the adapter’s plug on the laptop, sometimes the PA-10 will work. However, I get the message that the AC Adapter type is not recognized and the laptop will not run optimally. I have a choice to press F1 to continue or F2 to setup, etc. I press F1 and the laptop will boot. (This only works on the PA-10. It does not work on the 2 PA-12.) Unfortunately, the laptop will be working and suddenly decides it does not have power and turns off. All along, I thought I have a defective jack (since moving the adapter wire sometimes works). However, I have another PA-12 at work. So, I plugged my laptop to that adapter (my 3rd PA-12), and everything works. It charges the battery and runs the laptop without the battery.

My question, is something on the laptop causing the AC adapters to fail? So far, I have 3 adapters that are not working. I fear my 4th adapter will go the same way. Is this a bad jack issue (I bought replacements jacks just in case). Also, why did the laptop suddenly stop recognizing the adapters? Is there anyway I can fix the 3 adapters? (I’ve checked all 3 adapters with a voltmeter, they all put out the correct near 19.5 v). I’ve also gotten to the point where I have the motherboard out of the laptop, but, there is a steel casing around the jack and motherboard. How do I remove it?

cj2600

RobertM,

I agree. It takes more time to remove the nine pin power jack from a Dell laptop, it’s very solid.

I can remove most power jacks from Toshiba motherboards in 2-3 minutes, but when I work with Dells it takes some time and effort.

cj2600

Rami,

It’s a power fuse. I believe it doesn’t matter how you solder the fuse, it could be solder both directions.

cj2600

Lisa,

I think you are talking about the power connector board. The HP part number for this board is: 382414-001

Google the part number and you’ll find it.

If you look at Google images, you’ll see the board. Is it the right one?

cj2600

Cathy,

Do you have another Dell laptop at work? Can you test that laptop with your adapters?

I think there could be a problem with your motherboard but I’m not sure what’s going on. I guess you’ll have to take a closer look at the power jack and see if it makes bad connection with the motherboard.

In order to remove the motherboard you can follow these instructions.

Cathy

cj2600:

Unfortunately, I am the only one with a Dell (I work in a 3 people office where I use my personal laptop for work stuff), so, no one can help me test the adapters.

I have followed the instructions to remove the motherboard. But, the motherboard still have a steel casing on top even when I pull it out of the laptop shell.

Cathy

I found someone with the same laptop and tried all 3 adapters. They worked. I guess it is my jack or motherboard. But, of my 4 adapters, why did 3 fail and 1 work (and is still working)?

cj2600

Cathy,

So, your laptop fails with these 3 adapters but another laptop works just fine with same adapters. Apparently, there is nothing wrong with the adapter but there is a problem with the motherboard in your laptop.

To be honest, I don’t know.

I don’t remember this laptop off the top of my head. If the motherboard comes out with a metal frame, in order to access the power jack you’ll have to separate the motherboard from the frame.

Mike

GREAT INSTRUCTIONS! Just replaced my Gateway 3545gz’s jack last night. Didnt even have to take out the motherboard. 2hrs and an extra $150 in my pocket.

andy

wow,, i been wondering how to do it ,, this is really helping everyone including me. thank.. i wish you have the instruction in video .. if you u do please pose all your knowledge is would help more people. thank you.. nice work.

John Smith